Filtration membranes are used in filter press systems to separate solids and liquids in various types of suspensions. The medium is squeezed out under the action of pressure and temperature in a large number of chambers consisting of filter plates with filter membranes installed on them.

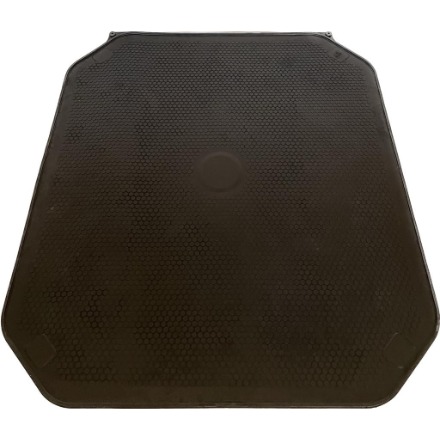

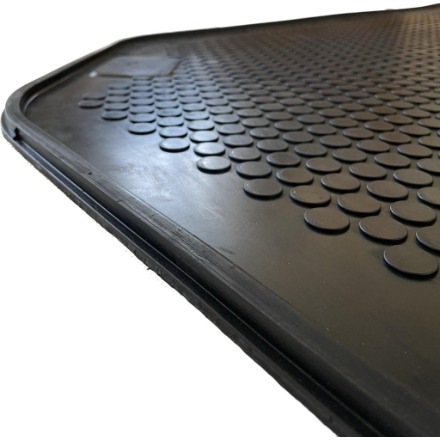

In the brewing industry, the most common membrane is the EPDM membrane (Shore A) with dimensions of 1800 x 2000 cm (2 by 1.8 m2) and is ideal for Meura 2001 filter press.

EPDM elastomers provide excellent resistance to heat, water, and steam as well as to alkaline solution (e.g. a 2% alkaline solution) which can be used for CIP purposes. Since the membrane comes into contact with food/beverage, a food grade certificate is available to ensure compliance with numerous food safety standards.

Process of wort clarifying (lautering) in a mash filter

Mashing is usually a process step in brewing in which ground grains and water are combined and heated to form and extract sugars and other components from grains to form a mash, which is a suspension of wort and hard grains. In order to carry the wort further into the brewing process, it must be separated from the grains into the mash in a mash filtration or lautering process. In large breweries, this is usually done with a mash filtration unit.

The membrane is used to apply pressure to the mash so that the wort is pushed through the filter out of the mash.

After a certain number of brews, the structural integrity of the membrane is compromised, so the membrane needs to be replaced. According to the feedback of our customers, on average, the membrane works perfectly for 6000 brews. But you should always keep in mind that everything depends on the intensity of beer production at the brewery.